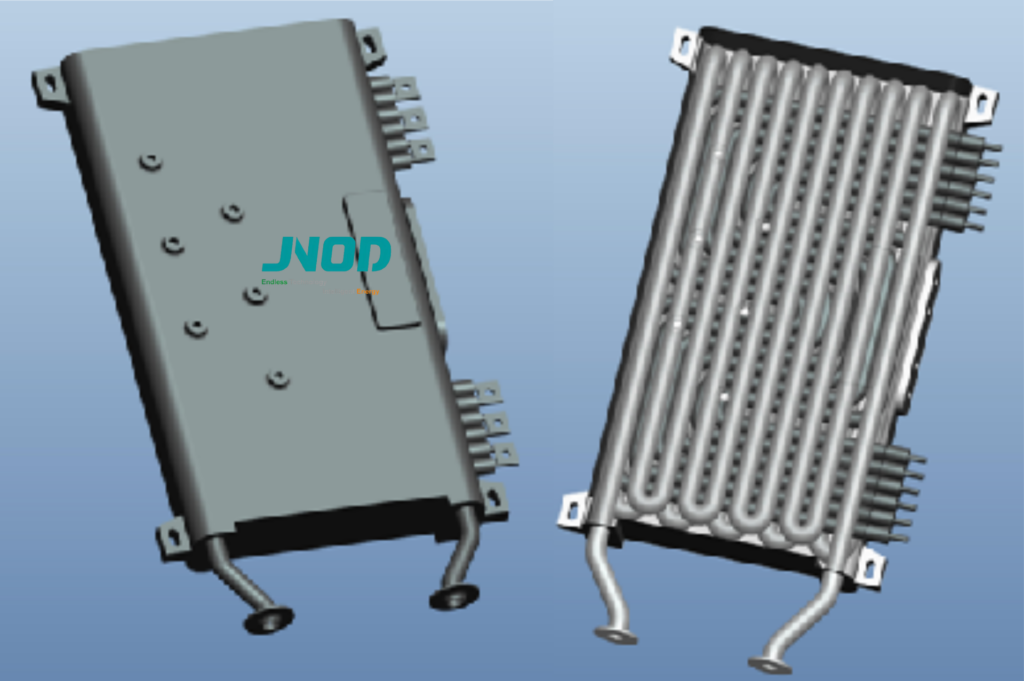

Traditional U-Shaped Heating Elements VS Cast Aluminum Heating Elements

Electric heating elements are the core components of electric boilers and electric heating systems. Their design and material directly affect heating efficiency, safety, lifespan, and maintenance costs.

Among the most common options on the market are traditional U-shaped heating elements and cast aluminium electric heating elements. This article compares these two technologies in detail, explains what an electric heating element is, how it works, and helps you choose the better solution for long-term performance and reliability.

What Is an Electric Heating Element and How Does It Work?

An electric heating element converts electrical energy into heat energy. When electric current passes through a resistive material inside the element, resistance generates heat, which is then transferred to water or another medium to provide heating.

The heating element is responsible for providing the electrical energy to be converted into heat energy, maintaining a stable and safe temperature output. The efficiency of this process depends heavily on the heat conduction medium, material, surface temperature, and contact with water.

Heat Conduction Medium Comparison

Traditional U-Shaped Heating Element

- Medium: Water

- Heat is transferred directly from the metal tube to the water.

Cast Aluminium Heating Element

- Medium: Aluminium

- Heat is first conducted through aluminium, then transferred indirectly to water.

Aluminium has far superior heat transfer properties, which significantly improve efficiency and safety.

Thermal Conductivity of the Medium

U-Shaped Heating Element

Thermal conductivity: 0.54 W/m· K

Low conductivity leads to higher surface temperatures and uneven heat transfer.

Cast Aluminium Heating Element

Thermal conductivity: 237 W/m· K.

Excellent conductivity allows faster, more even heat distribution. Higher thermal conductivity means lower operating temperature and higher system stability.

Surface Temperature and Safety

U-Shaped Heating Element: High surface temperature. Increased risk of overheating due to poor heat transfer. Scaling worsens heat dissipation over time

Cast Aluminium Heating Element: Low surface temperature. Element surface temperature does not exceed 85°C. Operates at full power without overheating

Lower surface temperature greatly reduces the risk of burnout and improves safety.

Contact with Water and Scale Formation

U-Shaped Heating Element: It comes into direct contact with water, making it prone to scale formation. Scale buildup reduces efficiency and increases energy consumption.

Cast Aluminium Heating Element: It is completely isolated from water, preventing scale formation on the heating element. Its performance is stable and unaffected by water quality.

This makes cast aluminium heating elements especially suitable for regions with hard water.

Leakage and Structural Reliability

U-shaped Heating Element: It has a welded U-shaped cup structure, and the welded areas are prone to corrosion, thus posing a higher risk of perforation and leakage.

Cast Aluminum Heating Element: It has no welds; it’s a one-piece design, therefore, it can withstand high water pressure and has no risk of leakage.

The one-piece structure significantly extends service life and reduces maintenance.

Heating Efficiency Over Time

U-Shaped Heating Element: Its heating efficiency decreases as scale builds up. Its energy consumption increases over time.

Cast Aluminium Heating Element: It maintains a heating efficiency of over 96% throughout its entire lifespan. Its performance is stable and does not degrade.

Long-term efficiency means lower operating costs and better energy savings.

Temperature Rise and Element Lifespan

U-Shaped Heating Element: Scale buildup can cause heat to concentrate, easily leading to core burnout and element explosion.

Cast Aluminum Heating Element: It distributes heat evenly, eliminating the risk of localized overheating. Therefore, they have a longer lifespan.

Stable temperature control ensures reliable operation even under continuous use.

Conclusion: Why Cast Aluminium Heating Elements Are the Better Choice

When comparing traditional U-shaped heating elements with cast aluminium electric heating elements, the advantages of cast aluminium technology are clear:

- Higher thermal conductivity

- Lower surface temperature

- No scale formation

- No leakage risk

- Over 96% lifetime efficiency

- Improved safety and durability

For electric boilers and modern electric heating systems, cast aluminium electric heating elements offer superior efficiency, reliability, and long-term value, making them the preferred choice for both residential and commercial applications.